Check out Bay Area Circuits at bayareacircuits.com!

Circuit boards are an essential part of our solar car, handing all of the controls and communication between the various systems of the car. On CalSol, the electrical team is responsible for designing and programming the printed circuit boards (PCBs) required to operate the solar car. From a complex board that monitors the status of the battery to a simpler board that reads how much the brake and accelerator pedals are pressed down, each PCB reads data from sensors that it’s connected to, processes the information, and transmits it to the rest of the car.

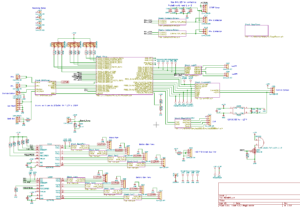

We start designing each board with high-level block diagrams of circuit components, and develop these into a schematic that outlines how all of the parts will be connected.

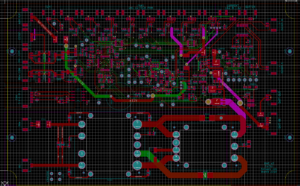

Next, a layout is made to package everything like how it will be on the circuit board.

Finally, we send the completed board designs for manufacturing. Bay Area Circuits (BAC) is a long-time sponsor of CalSol, and generously manufactures PCBs for us to code, test, and run on the car for no cost. Thanks to them, we can take our designs from ideas to reality and build the best car we can. We encourage you to check out their website at bayareacircuits.com!

We recently switched to using 4 layer circuit boards, as opposed to simpler, easier-to-manufacture 2-layer boards. Using 4-layer PCBs allows us to use smaller boards by accommodating a higher part density along with more resistance to electromagnetic interference (EMI), both of which improve the electrical system of our solar car. While this makes the design easier, they are harder to fabricate. Bay Area Circuit’s willingness to help us with this more complicated process has greatly streamlined our designs, allowing us to spend more time on other aspects of creating a solar car. BAC has also provided us with engineering support and design advice, helping us learn best practices for designing printed circuit boards.

Thanks to BAC’s fast turnaround, we are able to make multiple versions of each board to iterate through designs and correct mistakes before they become a part of the car. We were able to assemble a test bench with our first run of boards to begin testing our firmware. We connected everything in a configuration similar to how it will be on the car, enabling us to test the full system before it is integrated into the actual car.

The test bench helped us verify that all of the boards are functional, but we also had to fix many small mistakes. We’ve received and almost completed soldering the next iteration of circuit boards, which will be the ones powering Tachyon!

Written by Elizabeth Li