Impulse is nearing completion! With the completion of the shells and the rear suspension, the final chassis connections for the towing points have been welded and the access windows have been cut in the shell.

While ultimately the goal is to never have to use the towing points, in the case that we do need them, the design objective is to minimize their interference with other systems. They need to be inconspicuous, yet functional and up to regulation standards.

To meet this goal, at first the towing points were designed so that in their resting state they would require absolutely no alteration of the shell. From connection points at the frontmost and rearmost ends of the chassis, nylon webbing with a large steel o ring at the end would be coiled around hooks near the front and rear fairings. In the event of an emergency, one would reach through the opening in the fairing, pull out the webbing and latch a towing hook to the rings. While this design satisfied the regulations and preserved the aerodynamics of the shell, it also relied heavily on the hope that such an emergency would never occur.

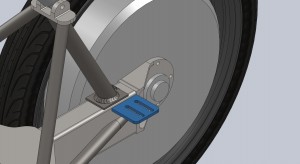

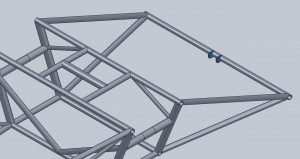

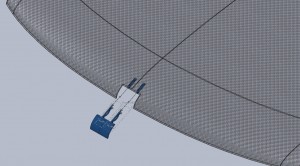

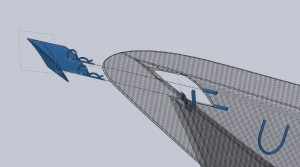

After some debate and deliberation, it was painfully conceded that in order to make the towing points safe and practical, rather than simply legal, windows would have to be cut in the shell to allow access to the towing rings. These would be relocated at the true front and rear of the car rather than at the bottom near the wheels to reduce the angle of elevation of the tow straps in deployment, thereby putting stress on the chassis, not the shell. To prevent damage to the chassis itself, the towing straps would simply be tied onto the beams of the chassis, held in place with small metal tabs, and knotted cleverly so that they would tighten rather than loosen under the tension of towing. For the same purpose, the rear connection tab would be relocated from the chassis to the rear suspension.

Thanks to collaboration with the shell design team, it was possible to make these modifications such that they would minimally impact the aerodynamic properties of the shell by locating the windows as close to the stagnation point of the car as possible. Unfortunately, even this aspect itself needed to be redesigned, as the stagnation point occurs at the seam of the top and bottom shells, and a window cut between the two halves would unnecessarily complicate construction. Of course, the alteration required here was very small–the window was simply elevated slightly to only be on the top shell. But the kinks in the realization of the towing points has been a lesson in that even apparently minor systems require tight communication between separate design teams, and need close scrutiny, revision, and compromise.