The last three weeks has seen a whirlwind of activity from CalSol as dozens of us have pushed even harder than before, toiling away mornings and nights to finish all of our carbon fiber layups. Too many nights have the clocks turned to 1am just to be back at 9am that same day, but we love seeing the massive push of progress. We just entered Spring break and those involved are taking a very well deserved rest for a day – just one – then back to work Monday!

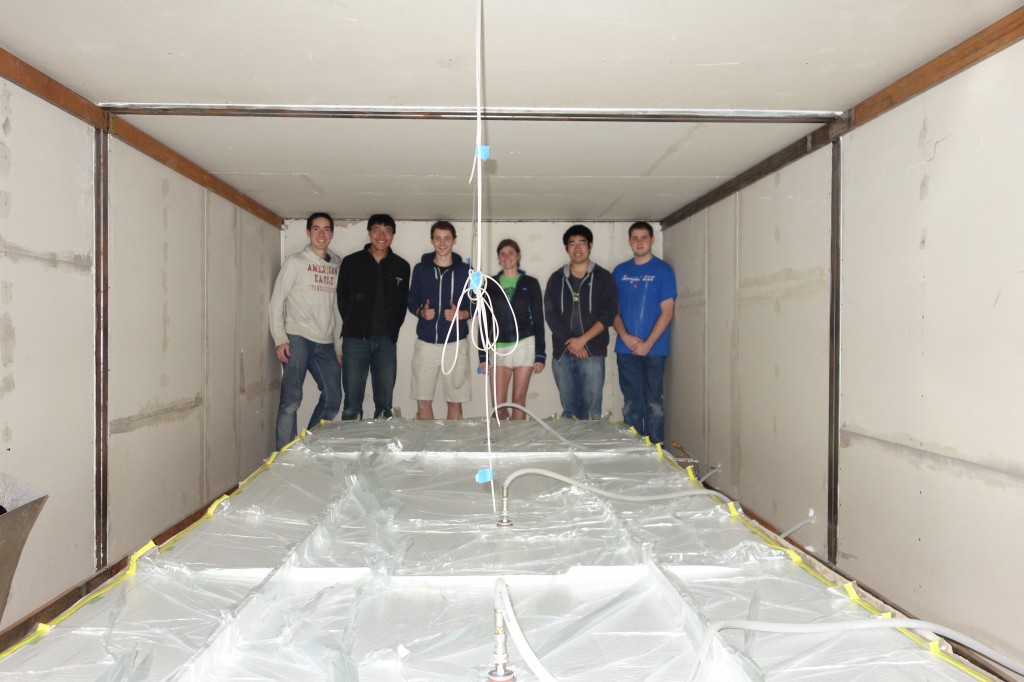

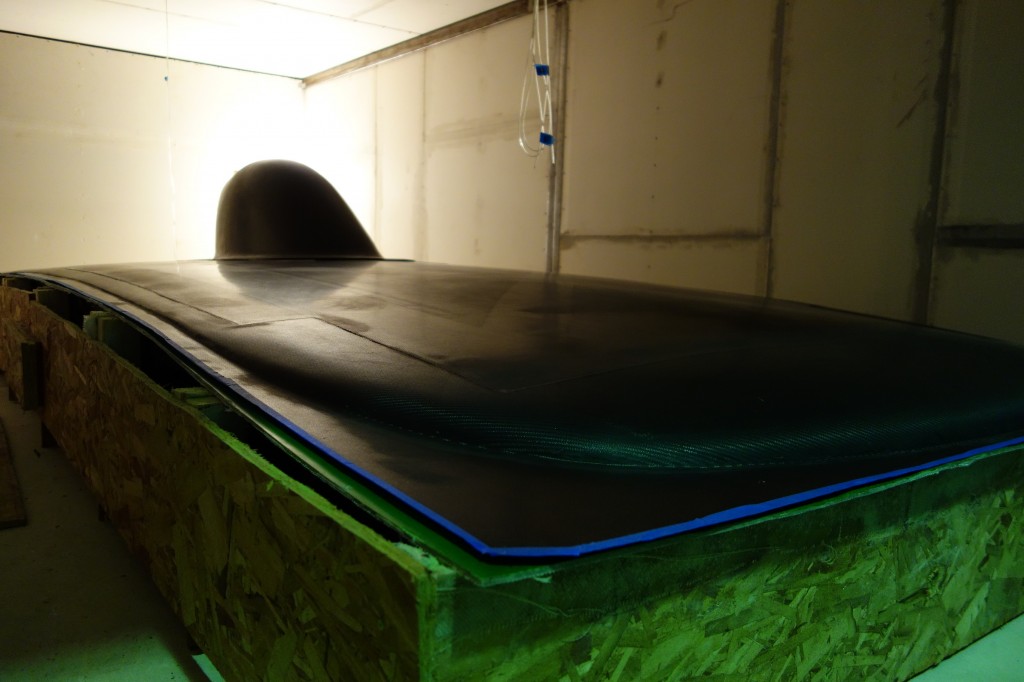

Zephyr is being built with a brand new manufacturing method for the team called pre-impregnated carbon fiber and Sam – shell lead – has been the champion of this process. He put in the hours to prep work and designs for the entire rest of the team to help implement. Long rolls of carbon fiber fabric impregnated with thermoset resin is laid out onto our smooth, waxed mold surface. Then CalSol members smooth and stick the fabric to the mold using heat and pressure making sure that there are zero wrinkles or air bubbles in the surface. This process is repeated with a smattering of nomex core, foam, and uni-directional carbon fiber in various areas all to increase the stiffness of the final product. Once satisfied, a release fabric is applied to the carbon fiber, then a cottony breather fabric, and lastly a large vacuum bag encases all of the carbon. Vacuum pumps suck the air out of the bag and press the carbon fiber into our smooth mold. Finally, we close the oven door and bake the carbon fiber to set the resin in place.

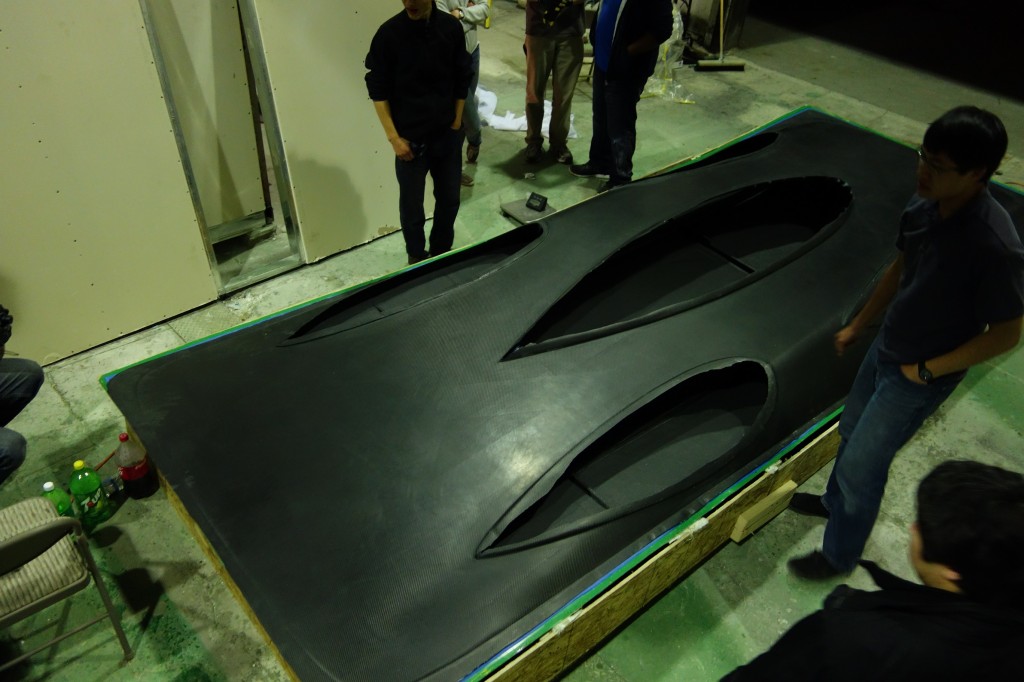

Quite a long process right? But now we are proud to say that we have finished all of the layups! We would also like to thank Patz Materials and Technologies for their help in making the pre-impregnated carbon fiber for us

Please enjoy the following photos that outline our thousands of man hours spent over the last 3 weeks.